Proper Use of Warning Lines on Construction Sites: A Guide

Ensure construction site safety in Portland, Oregon with our guide on proper use of everlasting and cone and base warning lines. Learn essential tips for effective implementation.

Maintaining safety on job sites is crucial. At Steve Garlock Equipment, we understand the importance of using effective warning lines to protect workers and pedestrians. Here's a comprehensive guide on the proper use of warning lines, including everlasting warning lines and cone and base warning lines, to ensure your construction site is secure.

The Importance of Warning Lines

Warning lines are essential for marking hazardous areas on construction sites. They help prevent accidents by clearly indicating danger zones and keeping workers and equipment within safe boundaries. Proper use of warning lines can significantly reduce the risk of falls, collisions, and other incidents.

Everlasting Warning Lines

Everlasting warning lines are durable and designed for long-term use. Here’s how to properly implement them:

- Installation: Securely anchor everlasting warning lines to stable points around the hazardous area. Ensure the lines are taut and clearly visible.

- Maintenance: Regularly inspect the lines for wear and tear. Replace any damaged sections immediately to maintain effectiveness.

- Visibility: Use brightly colored lines, often with reflective properties, to enhance visibility during low light conditions and ensure they are noticeable from a distance.

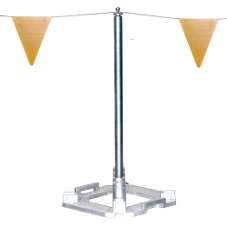

Cone and Base Warning Lines

Cone and base warning lines are versatile and easy to set up. Here’s how to use them effectively:

- Setup: Place cones at regular intervals around the designated area. Attach the warning lines to the cones, ensuring they are at an appropriate height to be seen clearly.

- Flexibility: These lines are ideal for temporary or frequently changing construction sites. They can be quickly adjusted or moved as needed.

- Stability: Ensure cones are weighted or secured, especially in windy conditions, to prevent them from tipping over and compromising the safety boundary.

Best Practices for Using Warning Lines

- Clear Communication: Inform all workers about the purpose and location of warning lines. Use signage to reinforce the message and ensure everyone understands the safety protocols.

- Regular Inspections: Conduct daily checks to ensure warning lines are intact and positioned correctly. Address any issues immediately to maintain site safety.

- Compliance with Regulations: Adhere to OSHA guidelines and local regulations regarding the use of warning lines. This ensures your site meets legal safety standards and protects your workforce.

- OSHA: OSHA regulations require warning line to be a minimum of 15ft from the fall hazard to warn someone that they are approaching danger and if they do go past they MUST be connected to a fall prevention device or have safety rail in place at the edge of the roof.

Conclusion

Implementing and maintaining proper warning lines on your construction site is vital for ensuring safety and preventing accidents. Whether you choose everlasting warning lines for long-term projects or cone and base warning lines for their flexibility, understanding their proper use is essential.

At Steve Garlock Equipment, we are committed to providing the best safety solutions for construction sites in Portland, Oregon. For more information on warning lines and other safety equipment, contact us today.